Home / All / Construction Industry /

Antioxidant Newantox IPPD (4010NA) in Conveyor Belt Applications: A Comprehensive Solution

Antioxidant Newantox IPPD (4010NA) in Conveyor Belt Applications: A Comprehensive Solution

Antioxidant Newantox IPPD (4010NA) in Conveyor Belt Applications: A Comprehensive Solution

Background Introduction

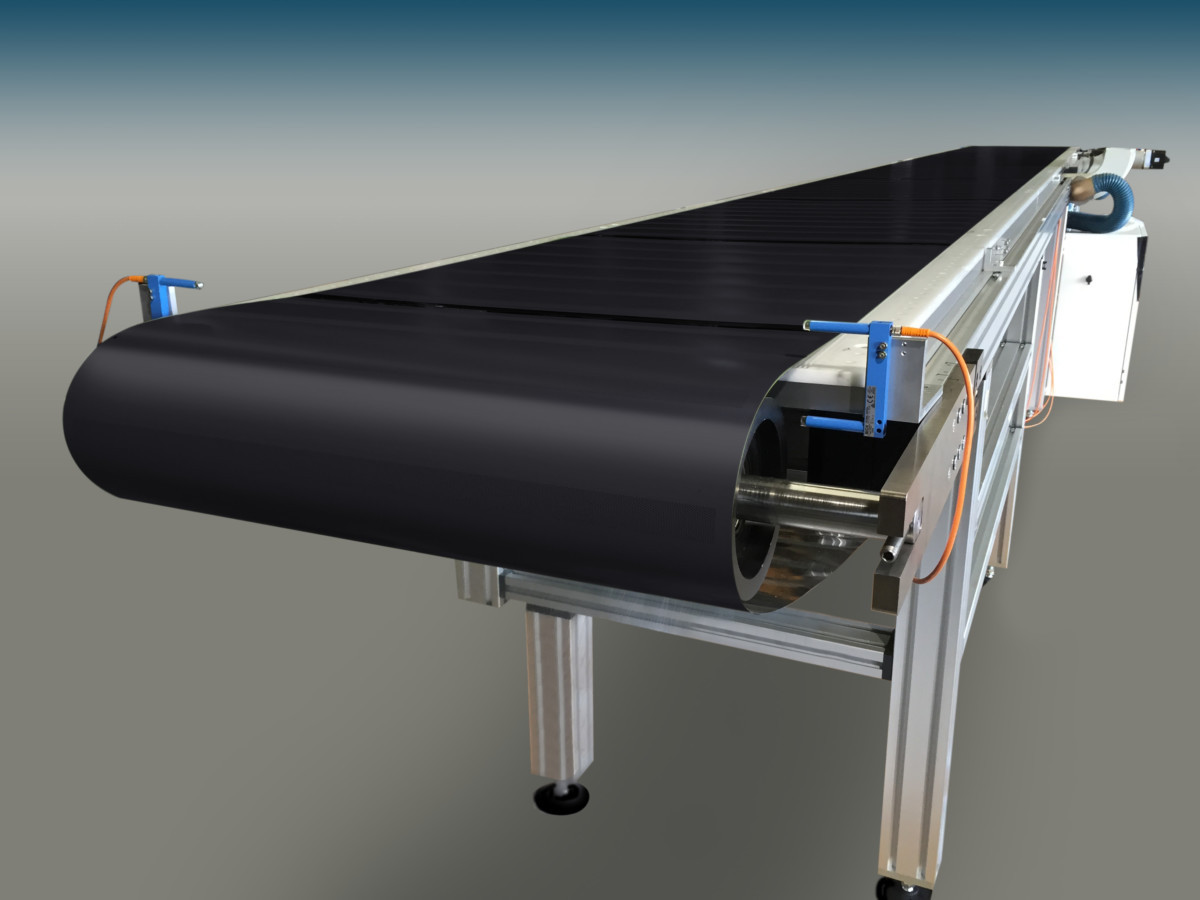

Conveyor belts are crucial components in many industries, including manufacturing, mining, and logistics. These belts endure constant mechanical stress, exposure to chemicals, UV radiation, and varying environmental conditions, which accelerate the aging and deterioration of rubber materials. To maintain optimal performance and durability, conveyor belts require effective antioxidants that can protect them from oxidative degradation and environmental damage. PolyAdds Antioxidant Newantox IPPD (4010NA) has become a trusted solution in extending the service life of conveyor belts and improving their overall reliability.

Pain Point Analysis

Oxidative Aging: Continuous exposure to oxygen and heat accelerates the oxidation process, leading to loss of flexibility and strength in rubber materials.

Mechanical Wear and Tear: Conveyor belts often face high levels of mechanical stress, causing premature breakdown of the rubber.

UV and Ozone Exposure: UV radiation and ozone exposure cause rubber cracking and embrittlement, especially in outdoor or high-UV environments.

Chemical and Temperature Variability: Conveyor belts in harsh environments are exposed to chemicals and extreme temperatures, leading to material degradation and reduced lifespan.

These issues result in costly maintenance, frequent replacements, and downtime, which impact productivity and operational efficiency.

Problem-Solving Solution

Antioxidant Newantox IPPD (4010NA) is an advanced antioxidant specifically designed to protect rubber compounds used in conveyor belts. Its key advantages include:

Enhanced Oxidation Resistance

Effectively neutralizes free radicals, preventing oxidative degradation of rubber and maintaining its mechanical properties.

Extends the service life of conveyor belts by reducing the effects of heat and oxygen exposure.

Superior Protection Against UV and Ozone

Provides strong defense against ozone-induced cracking and UV degradation, preserving the integrity of conveyor belts in outdoor or high-UV environments.

Helps maintain the flexibility and elasticity of rubber under extreme environmental conditions.

Improved Mechanical Strength and Durability

Enhances the rubber's resistance to mechanical stress, minimizing wear and tear during heavy-duty operations.

Contributes to overall durability, ensuring that conveyor belts perform reliably over extended periods of use.

Chemical and Temperature Resistance

Offers enhanced resistance to a wide range of chemicals, oils, and extreme temperatures, ensuring the longevity of conveyor belts in harsh industrial environments.

Cost-Efficiency and Reliability

Reduces maintenance costs by increasing the durability and performance of conveyor belts.

Lowers the frequency of belt replacements and downtime, resulting in higher operational efficiency and reduced total cost of ownership.

Implementation in Conveyor Belt Manufacturing

PolyAdds Antioxidant Newantox IPPD (4010NA) can be easily incorporated into the rubber compounding process, blending well with other ingredients to provide long-lasting protection against oxidative and environmental damage. This makes it an ideal choice for manufacturers producing conveyor belts for industries such as mining, automotive, food processing, and material handling.

Summary

Antioxidant Newantox IPPD (4010NA) is an effective solution for enhancing the performance and longevity of conveyor belts. By protecting rubber compounds from oxidation, UV degradation, ozone cracking, and mechanical wear, it helps ensure conveyor belts maintain their flexibility, strength, and durability over time. Its cost-effectiveness, combined with superior chemical and temperature resistance, makes it a valuable additive for industries seeking to optimize their conveyor belt systems and improve overall operational efficiency.